This document aims at explaining the corrective maintenance process in SAP.

In most organizations, the maintenance department’s main functions are the following:

Maximizing the availability of the physical assets

Keeping physical assets in a workable and safe state

Reduce the operating costs caused by equipment downtime and damage

In SAP, there are 5 types of maintenance processes:

Corrective maintenance: triggered by the detection of a defect

Preventive maintenance: work planned in advance

Breakdown maintenance: work that has to be executed in emergency

Calibration maintenance: ensures that precision instruments keep accurate measurements

Refurbishment maintenance: repair work done on materials subject to split valuation

This document will focus on the corrective maintenance process.

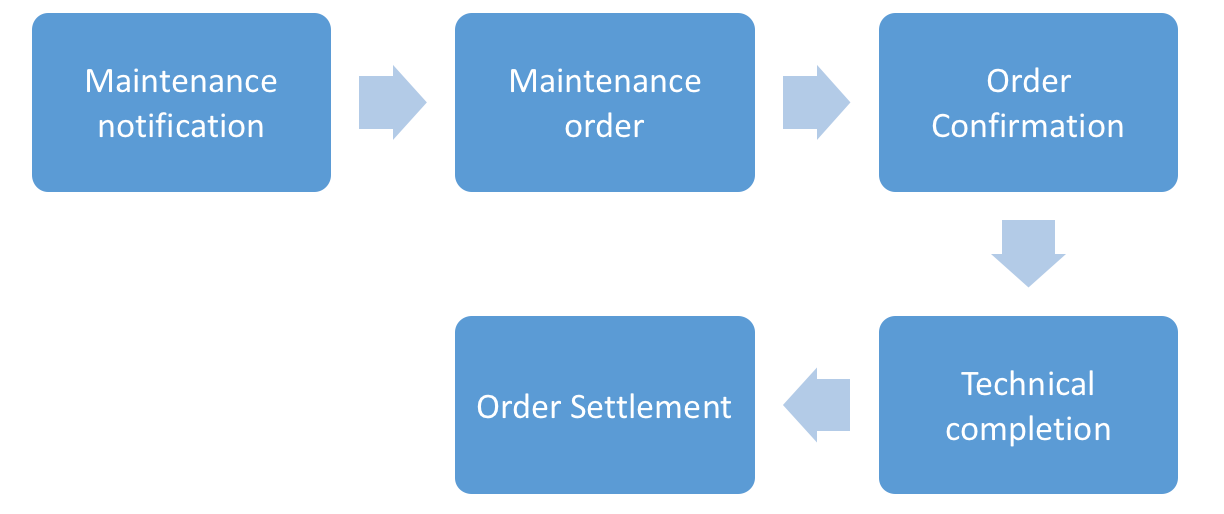

The maintenance order process follows five big steps.

The maintenance order process also has 3 types of roles involved: maintenance planner, maintenance supervisor, and maintenance technician.

We will now take a closer look at the five steps of the process:

1. Maintenance Notification

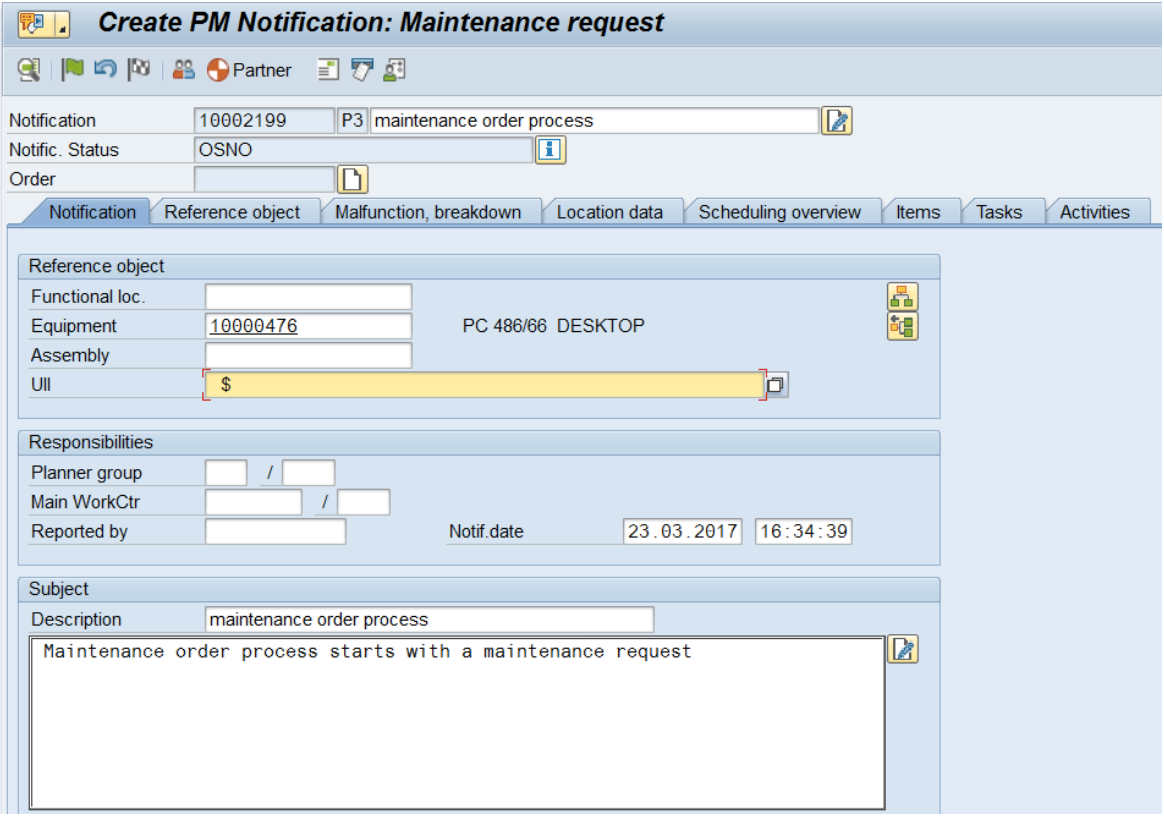

This document can be created by any of the 3 maintenance roles. The maintenance notification is triggered by the identification of a defect on a specific technical object. There are 3 types of standard maintenance notification: maintenance request, malfunction report and activity report.

The commonly used notification type is the maintenance request:

The creator of the maintenance notification can enter the technical object, the description of the issue and the main work center responsible for the work. After creation, the maintenance notification will be verified by the maintenance planner and the work will be dispatched among the maintenance technicians.

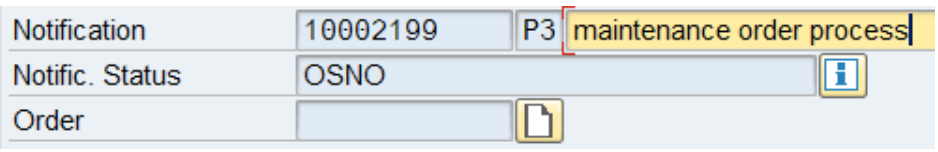

It is also possible to directly create the maintenance order from the maintenance notification header thanks to the creation symbol next to the field “order”:

2. Maintenance Order

The maintenance order can be created in 2 ways:

From the maintenance notification:

The maintenance notification will have the system status ORAS – which means “Order Assigned”.

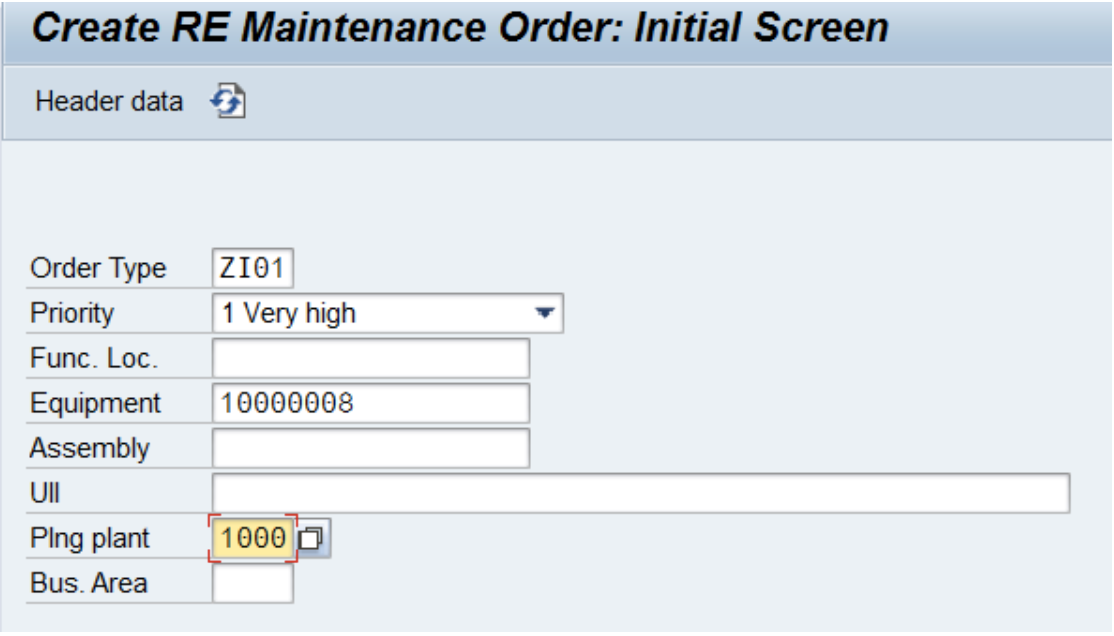

Directly through the transaction IW31

The maintenance order gets created with a certain order type, priority, technical object and a planning plant.

The typical structure of the order is as follows:

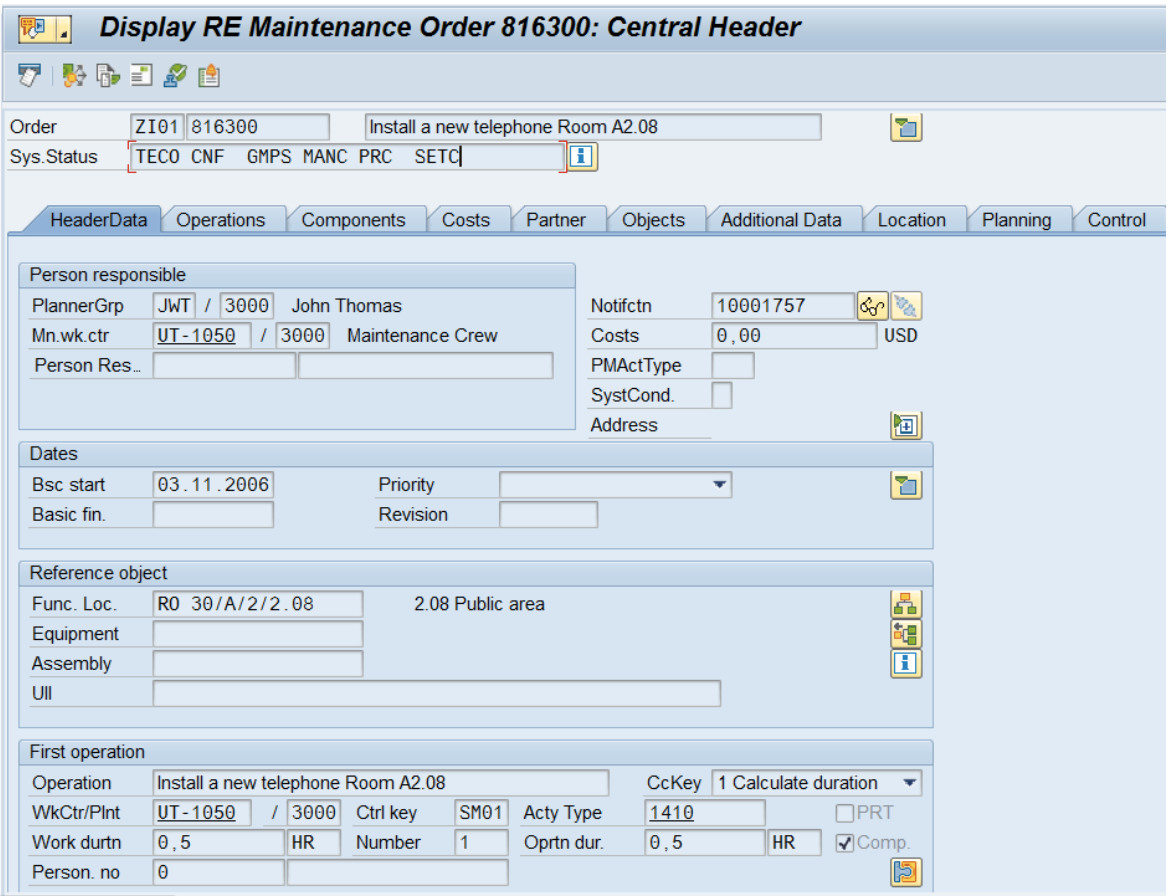

I provide you below with a high-level overview of what is the role of each tab in the maintenance order management process.

The maintenance order header data answers at a high level to the following questions:

Who: by displaying the “person responsible” sub-tab

When: by displaying the “dates” sub-tab

What: by displaying the “reference object” sub-tab

How: by displaying the “first operation” sub-tab (details are provided in the “operations” tab)

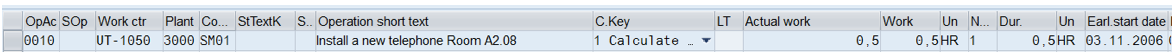

The operations tab provide details about which operations are done, by whom , in which sequence and for which duration.

The components tab is used whenever some materials are required for a specific operation

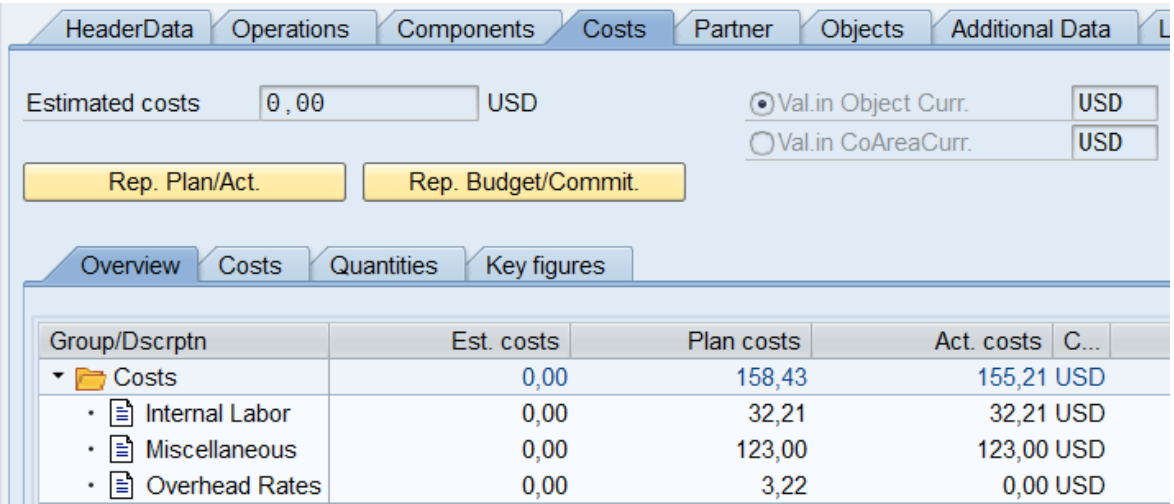

The costs tab is used to display the planned and actual costs

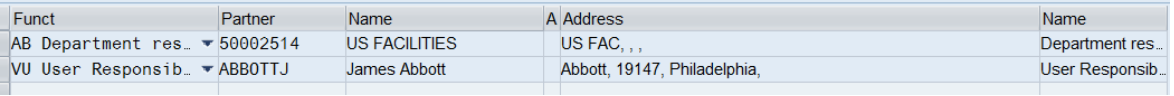

The partner tab is used to display the partners involved in the maintenance order.

The “objects” tab is useful whenever several objects are involved in the maintenance work. It also specifies, when applicable, which maintenance notification is linked to the order.

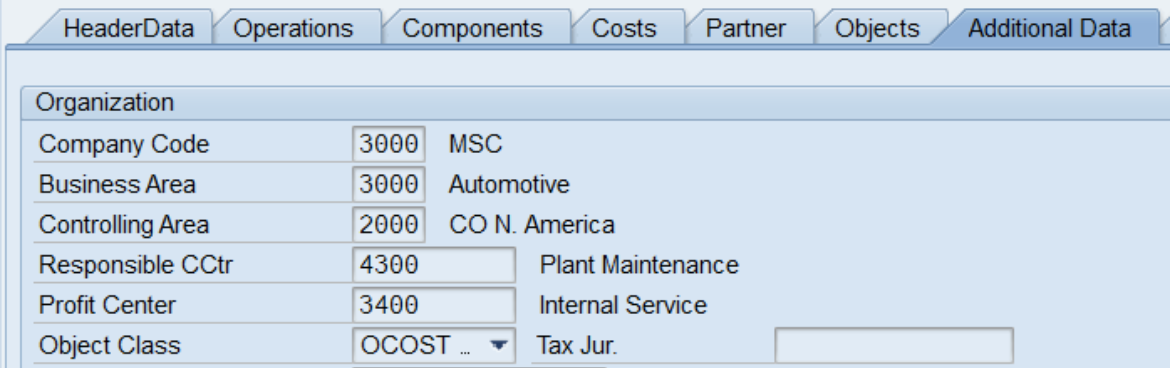

The “additional data” tab displays static finance-related organizational data. It has no impact on the process as such.

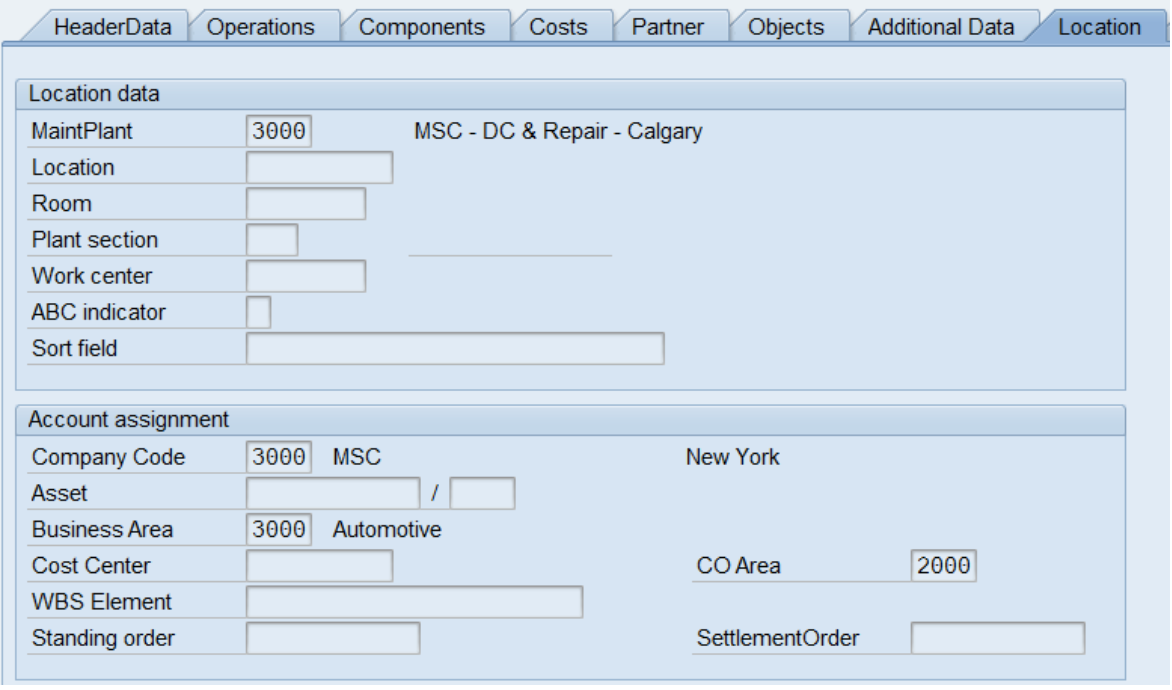

The “location” tab displays the “location” of the data from both a logistics and financial viewpoint: it displays the maintenance plant as well as the account assignment data for the order costs.

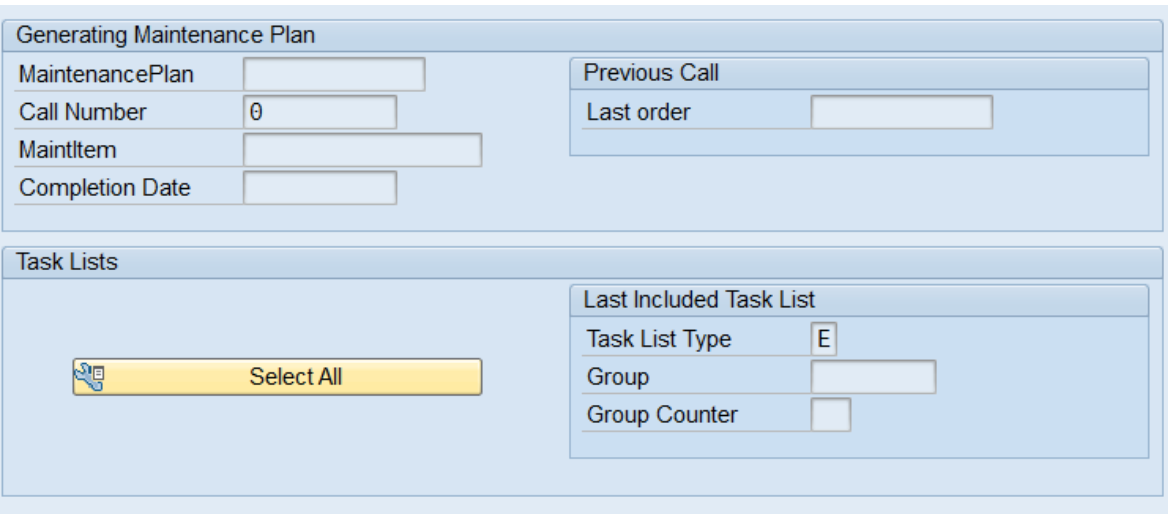

The planning data tab is not relevant for the corrective maintenance process. It is used in the preventive maintenance process. It displays the maintenance plan and the task list from which the preventive maintenance order is generated.

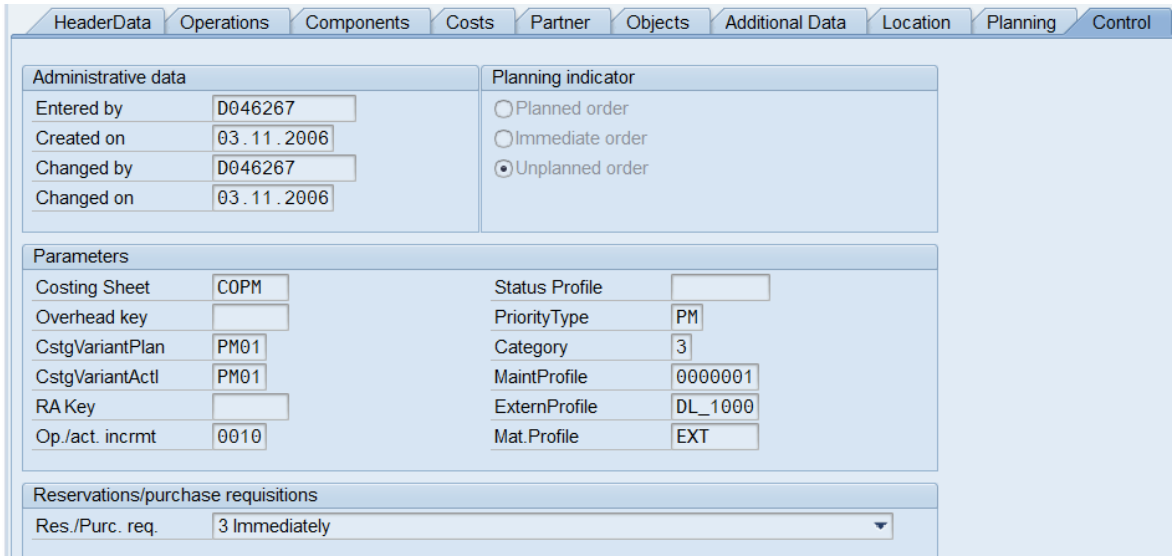

The “control” data contains the administrative data as well as the CO-parameters related to the order.

In case components are required for the order, the “reservation/purchase requisitions” sub-tab displays whether or not the documents are created immediately, after the release of the order or never.

3. Order Confirmation

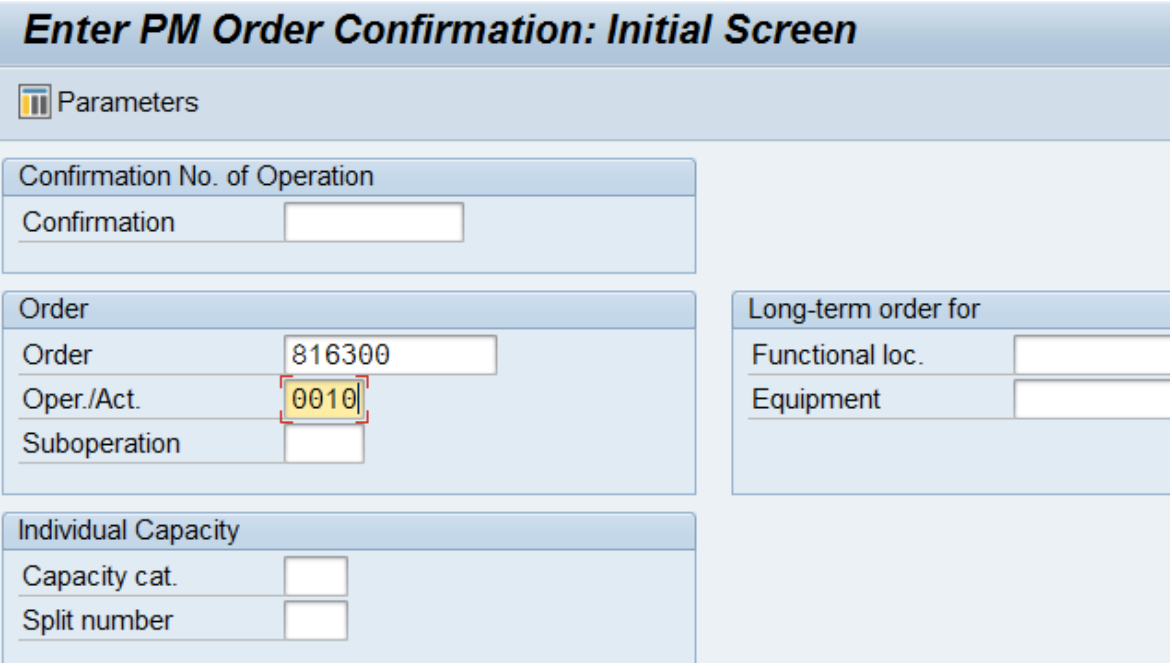

The confirmation on the maintenance order is done through the transaction IW41.

The confirmation is done at the operation level.

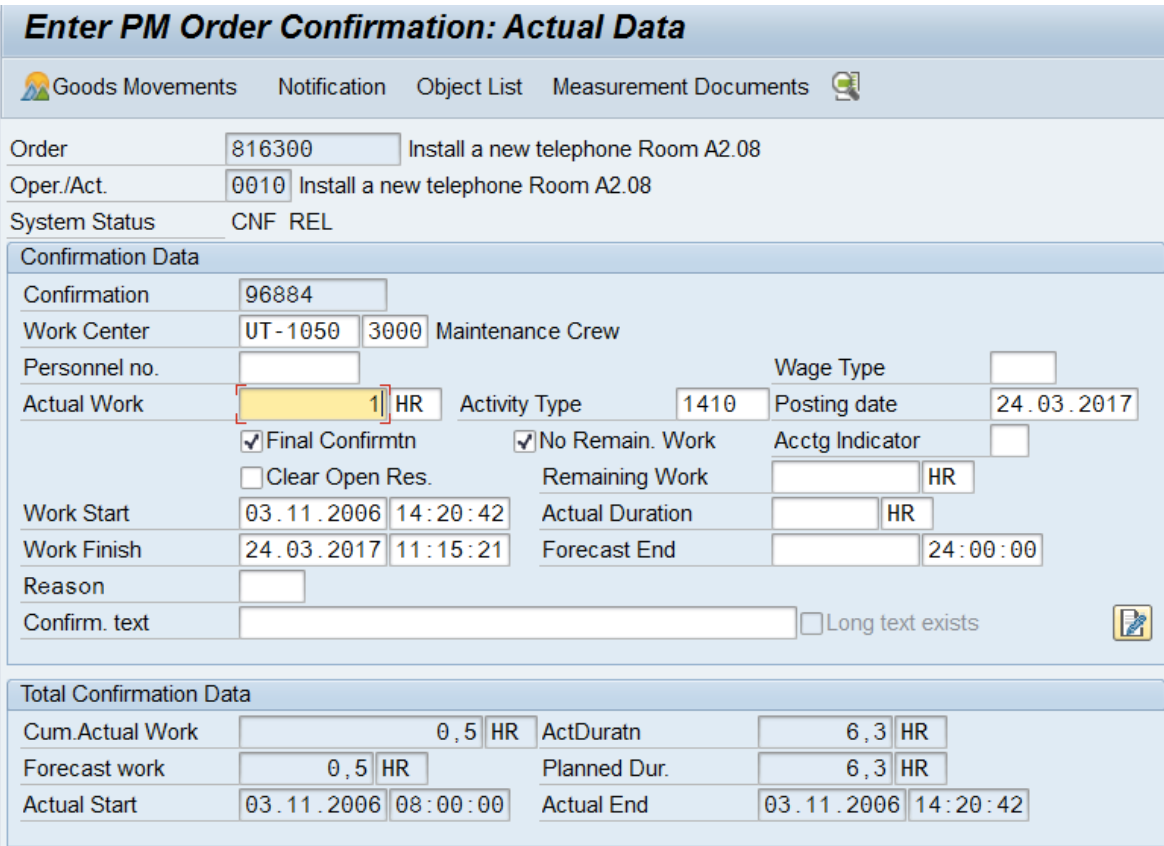

The confirmation document contains: the actual time spent on the tasks and, when applicable, the materials goods movements and measurement documents for technical objects. The “actual work” field has to be filled in to complete the confirmation. There is a flag for “final confirmation”. When it is flagged on, it means that there is no work remaining on the operation. When all the operations of an order are “final” confirmed, the order has the system status CNF.

After the confirmation is done, it is possible to display the variances between the planned and actual durations.

Several confirmations can also be done simultaneously through the transaction code IW42

4. Technical completion

When all the maintenance order operations are finally confirmed, the order can be technically completed. The technical completion of a maintenance is a handover of the work from the maintenance department to finance.

The technical completion is a standard system status only valid at the order header level. This status can also be cancelled in any maintenance order.

5. Order settlement

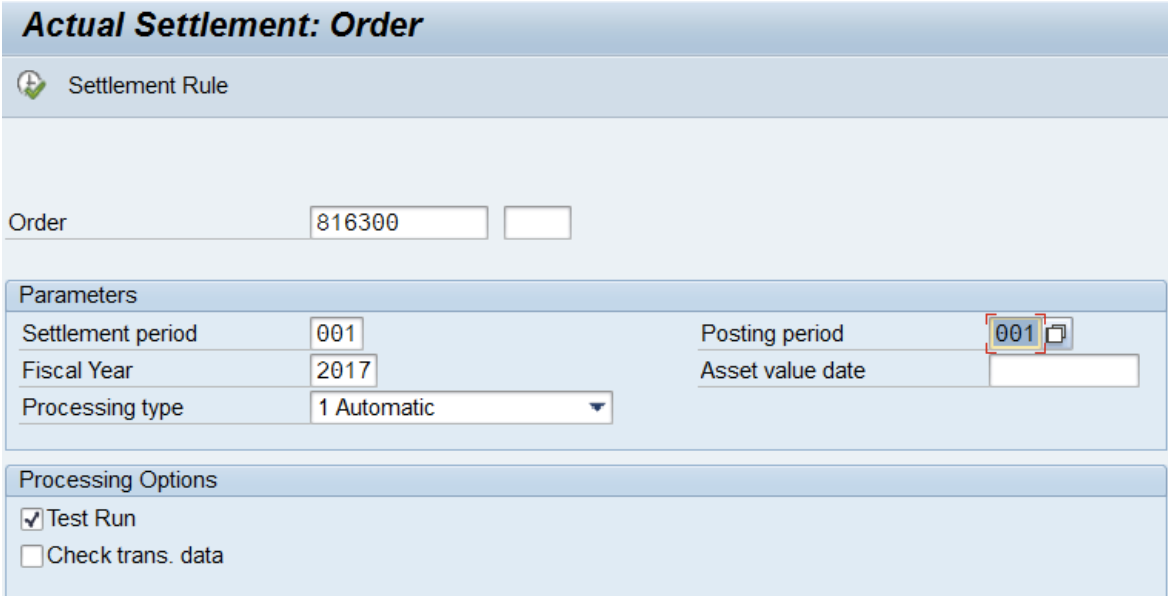

Settling a maintenance order means that all the actual costs incurred during order confirmation are sent to a “settlement receiver”. This settlement receiver is generally the cost center of the reference object (displayed in the header data). It can also be a specifically designated general ledger account. The settlement is done through the transaction KO88. The user needs to enter the order number, as well as fiscal year, posting and settlement periods. After that, the user decides whether or not he runs the settlement in test mode (with the test flag). The button “Execute” will run the settlement.

6. Key transaction codes

Most of the transactions used during the maintenance order management process are located within the following folders in the menu path: